|

History of Cement |

|

|

In the 18th century a big effort started in Europe to understand why some limes

possess hydraulic properties.

John Smeaton often referred to as "father of civil engineering in England" concentrated

his work in this field.

The French Engineer Louis Vicat, inspired by the work of Smeaton and Parker, began

a study of hydraulic limes in 1812 (published in 1818 as "Recherches experimentales

sur les chaux de construction". He reported that in the absence of naturally occurring

argillaceous components in limestone, quality hydraulic limes could be prepared

by the calcination of fixed ratios of clay proportioned with quicklime.

In 1818 an English patent was granted to Maurice Leger for "Improvement method of

making lime" (Leger used Vicat's method).

In 1822, the production of "British Cement" had been started by James Frost at Swanscombe

based on a patent for "a new cement or artificial stone".

The invention of Portland Cement is generally credited to Joseph Aspedin, an English

Bricklayer in 1824. It involves a double kilning such as was described by Vicat. |

|

In 1838 a young chemical engineer, Isaac Johnson, burned the cement raw material

at high temperature until the mass was nearly vitrified producing the modern Portland

Cement.

The German Chemist Wilhelm Michaelis proposed the establishment of cement standards

in 1875.

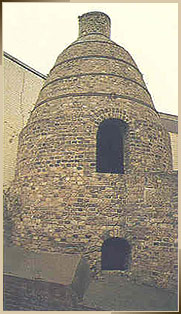

The earliest kiln is one of William Aspedin's bottle kilns from Robins & Aspedin

factory at Northfleet.

The earliest bottle or dome kilns were open kilns with tapered chimney to increase

the draft. They were burned in a batch rather than in a continuous fashion and were

charged with alternating layers of raw feed and solid fuel.

The chamber kiln was an improved design developed and patented by Mr. Johnson. The

combustion gases from the kiln dried the raw material so that when the kiln was

burned out a new charge of dried material is immediately ready for use.

The time and heat losses resulting from drawing the clinker, recharging the kiln,

and then heating it again led to the design of shaft kiln with continuous burning

of the materials, one of the main problem of the new kiln operation was the difficulty

of obtaining an even clinker burning, as some of the product would be greatly under-burnt

and others be much more heavily clinkered.

In 1898 Atlas Portland cement company according to Lewis improved the design by

using what is called a rotary kiln, this improvement was a big revolution in the

cement industry because the new kiln could produce 200 cement barrels per day compared

to a shaft kiln which produced only 40 to max 80 barrels per day; in addition to

quick improvement in this new design regarding the mixing, grinding equipments for

raw material, grinding equipments for coal, belt conveyor using mix kind of fuel

such as natural gas (1904, Iola Portland cement, Iola Kansas).

In practice, the operation with the first generation of rotary kiln (Ransone kiln)

was very difficult due to problem of maintaining a sufficient and uniform kiln temperature

with excessive balling of raw feed and sticking on the Frederick lining.

In 1899 Atlas Cement Company improved the technology of the rotary kiln and fuel

economy by replacing fuel oil with powdered coal dust. Furthermore, modifications

to the kiln were made by addition of two auxiliary clinker coolers, in which the

first hot discharged clinker was received as it fell from the kiln and air flowing

over it was heated and helped to ignite the coal dust in the rotary kiln.

The new clinker produced from the new kiln technology was different than the old

clinker especially from the setting time (much faster setting time). The French

chemist Pierre Giron solved this problem by adding gypsum to the cement in order

to control the setting time.

After 1900 there was rapid growth in both rotary kiln and auxiliary equipment technology

in the United States. Coal grinding mills were developed and coal burning in cement

kilns became the predominant combustion process in the industry. All the equipments

related to cement production crusher, raw mill, belt conveyors, bucked elevators

were improved.

Improvement in the following fields pertaining to cement manufacturing from material

science technology has been an ongoing process for 200 years.

Source: www.cimnat.com |

nike cortez

oakley

chaussures de foot

nike chaussure

nike schuhe

Scarpe

Adidas superstar

scarpe Nike

Scarpe

Cappelli

chaussures femme

Scarpe

Cinture

michael kors

air max

chaussure de sport

christian louboutin

nike air force

schmuck

chaussures sport

Nos Meilleures Ventes: Acheter Viagra, Cialis, Levitra en ligne

Levitra prix

Viagra 100mg prix en pharmacie, prix du viagra 100mg en pharmacie, viagra 100mg prix pharmacie,viagra prix,viagra pharmacie

viagra prix

KAMAGRA QUE ES,KAMAGRA GEL QUE ES,KAMAGRA 100 MG QUE ES,KAMAGRA ORAL JELLY QUE ES,KAMAGRA 100MG

kamagra 100mg

Cialis Prijs Belgie,Cialis Prijs Apotheek,Cialis Prijs Apotheek Belgie

cialis belgie

CIALIS PAS CHER,CIALIS GENERIQUE,CIALIS 20MG

cialis 20mg

Super Kamagra Belgique,Super Kamagra Avis,Super Kamagra Effet Secondaire

kamagra belgique

|

|

|